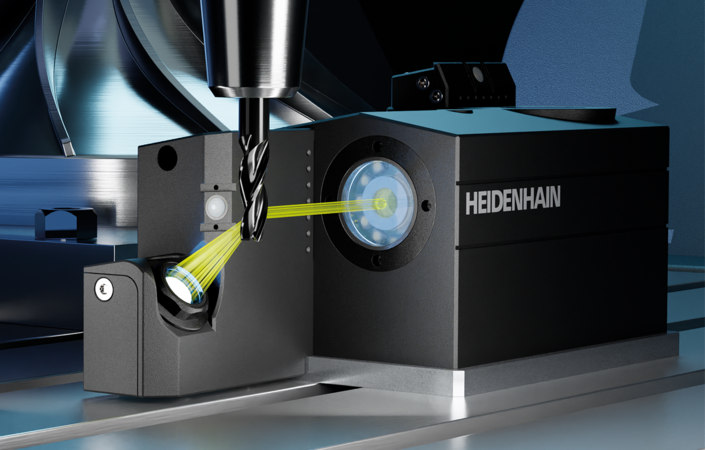

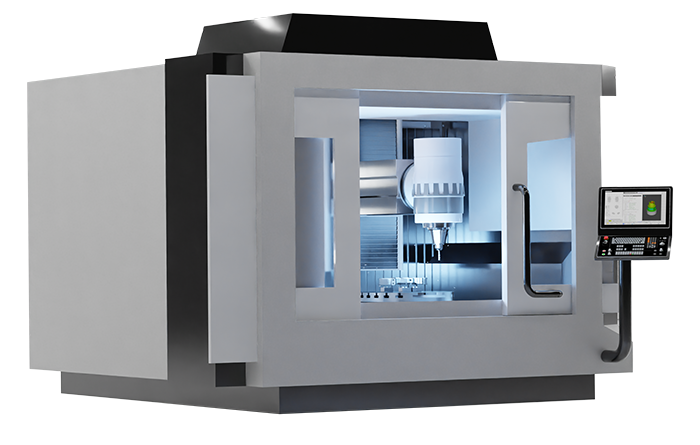

Touch probes and vision systems

HEIDENHAIN offers universal, high-accuracy touch probes for machine tools, enabling exact tool measurement, edge measurement on parts, and more. Proven technologies, such as wear-free optical sensors, collision protection, and integrated cleaning blowers, make these touch probes a dependable asset for tool and part measurement. The vision systems from HEIDENHAIN can also be conveniently deployed to monitor tools for even greater process reliability.